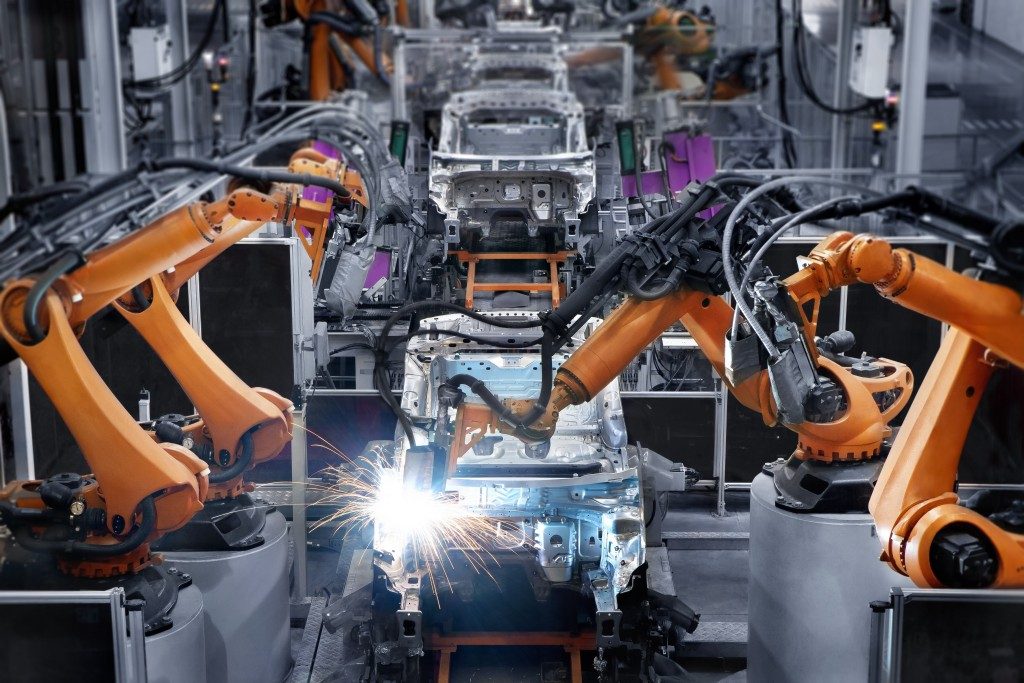

Truck body manufacturers and luxury carmakers all use the same materials to create their masterpieces—some just happen to be fancier than others. Most automobile manufacturers use the same steel for their proven track record in producing diverse and long-lasting vehicle bodies and parts.

Here are five of the most common metals used by truck body manufacturers:

Steel

Easily the heaviest part of any vehicle, steel is used extensively in manufacturing cars. The steel frame of a vehicle’s body, its roofs, trunk closures, and doors are formed by steel. Motor chassis or cages, drive train, and exhausts are also made of stainless steel.

Steel is the metal of choice in automotive manufacturing, thanks to its low cost, high strength in relation to weight, excellent formability, energy absorption in impact accidents, and recyclability. To make a steel alloy stronger, it is mixed with small amounts of other metals, such as chromium, manganese, tungsten, and vanadium.

Titanium

Rare and valuable, automobile manufacturers use titanium and its alloys for their high strength, light mass, damage tolerance, and resistance to aging factors such as corrosion and oxidation. They’re stronger than steel and weighs less than it. Titanium is primarily used for cold wound springs, exhaust systems, and internal combustion engines, though they have also been used for underbody panels on Tesla models, drive shafts and enclosures, and various low-quantity parts.

Because of its prohibitive costs, titanium is usually reserved for top car models and racing types. Steel is also easier to work with; it crumples,—unlike titanium—and dissipates the energy from crashes throughout the body of the car, making it safer during accidents.

Aluminum

Some manufacturers use aluminum for truck bodies to reduce their weight. Swapping steel for aluminum can eliminate 700 lbs off a truck. The lighter body makes for more fuel-efficient truck bodies that are corrosion resistant, durable, and safe. Its malleability and lightness have also helped it become the second most-used steel in automotive production, next to steel.

Aluminum is also touted as environmentally friendly. Energy efficiency is one eco-friendly advantage of aluminum, as the lightness of aluminum bodies reduces the amount of fuel required to accelerate vehicles. The metal is also highly recyclable and versatile without sacrificing the performance of vehicles.

Carbon Fiber

Though it’s not metal, carbon fiber is still worth mentioning in this list, as it is in the cutting edge of automobile fabrication. It is flexible, lighter than the lightest magnesium, and energy efficient like aluminum and steel combined. Furthermore, its malleable shape offers greater freedom in its shaping and structuring than traditional metals.

The strength of carbon fiber reinforced polymer composites or laminates also do not falter against stronger metals because of its woven layers. Yet this does not interfere with the fact that it comes with the stength of steel with one-fifth the weight.

As one might have guessed, all of these features come with a high price tag. Nothing less than racing and luxury types like the McLaren 570S boast carbon laminates for its structural panels and body frames. Shaped like a typical sports car with the weight of a tiny coupe, the $185,000 car is a proof of concept for carbon fiber’s usability—and expense

Automotive engineering continues to evolve. In 2018 alone, an electric sports car capable of going off-road, quick charging, surface coated brakes, and shape-shifting variable engines lead the way forward for advanced vehicular construction. As the need for cleaner, safer, and sleeker cars increases, so will the number of game-changing innovations.